Evolutionary Operation

In a previous post, we talked about how improving technology can help reduce carbon footprint, something that is in WOCU-Monitoring’s DNA. We continue to work to tackle the problem of climate change, and to do so, we explore any approach that allows us to improve our product or processes, which is essential for a monitoring tool that manages hundreds of thousands of devices.

In this new post, we will focus on optimizing processes within our monitoring operation.

The digitalization of production processes has led to the fourth industrial revolution. Industry 4.0 companies are those that have transformed their production processes to compete in a digital and globalized world. Several characteristics define Industry 4.0 companies, but in this case, we will analyze two in particular: operational flexibility and sustainability.

In our most important project currently, WOCU-Monitoring manages nearly half a million devices, a technical and organizational challenge. During the project design phase, an architecture was proposed that could support the initial deployment and subsequent growth, aiming to minimize operating costs as much as possible while always ensuring that the agreed service level agreements were met, something that ultimately had a decisive weight and made us very conservative, deploying the monitoring system on a virtualized platform that we later discovered was oversized.

The software optimization work resulted in a 50% reduction in energy consumption on the servers supporting WOCU-Monitoring, but we need to be more sustainable. The reality is that we all need to be more sustainable, and we must not skimp on research to achieve a total reduction in greenhouse gas emissions.

Our client is fully committed to this project, and for a period of time, we have been jointly researching the behavior of our monitoring platform, applying different architecture configurations.

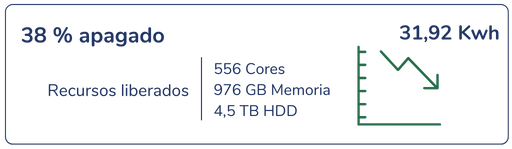

From the results of this research, we highlight the following:- Software performance improvements allow servers to handle more load; a small increase in resources (CPU and memory) is required to compensate for the new load.

- Less is more: the widespread use of satellite servers generates noise on the network, adding latency to monitoring checks.

In this post, we were going to talk about sustainability and operational flexibility; we still have the latter. Thanks to the application of flexible policies at the operational level, we are able to translate the research results into the real production environment.

- The use of virtual environments has allowed us to reorganize the entire monitoring system architecture.

- The flexibility of WOCU-Monitoring allows the monitoring environment to be adapted both in growth and decline.

- The implementation of flexible operational processes allows both companies to modify the project during its lifecycle, quickly adapting to the new environment.

WOCU-Monitoring, operational evolution.

In summary, we have optimized our environment to release renewable energy resources that can be redirected to different uses. Additionally, we have reduced hardware resource dependency through virtualization, allowing their reassignment to other services until the system reaches the end of its lifecycle. Thanks to this increased operational flexibility, we can continue to advance in our pursuit of sustainability and reducing our carbon footprint.