In a previous post, we discussed the rise of IoT devices and their drawbacks in terms of carbon footprint. In this new entry, we’ll talk about their advantages and how Industry 4.0 companies have adapted this technology, enabling them to remotely manage industrial processes.

The digitalization of traditional industrial processes, known as OT, has led to improvements in efficiency, visibility, and security in production environments, reducing operational costs. Analyzing OT data combined with business information allows for more robust strategic and operational decision-making.

On the other hand, there’s the challenge of monitoring the tens of thousands of IoT devices that large industries have deployed in their digitalization processes. Supervision is essential to ensure their proper operation and security, especially considering that they control strategic sectors of the production framework, such as energy production or water and gas supplies.

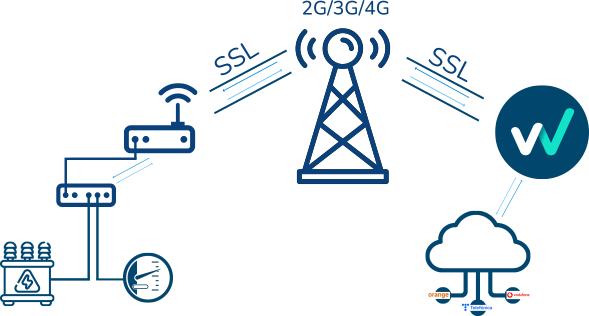

Within the production or energy supply sector, wireless communication services (obsolete 2G but necessary to maintain the ECall service, 3G to be phased out by 2025, and 4G) have expanded the management capabilities of industrial elements in isolated environments, increasing the volume of unattended devices that still require supervision.

At WOCU-Monitoring, we have developed specific monitoring to provide a solution for remote OT environments.

What Does WOCU-Monitoring Do?

We collect and process information from M2M devices to check their operation and security, thus guaranteeing communication and access to the devices that control production processes.

How Do We Do It?

Through programmable checks, we collect information about hardware, connectivity, and system performance parameters. Once the connection is established via an encrypted link with the multi-SIM device, the following information is obtained: active SIM, number of switches of the same, ICCID, IMSI, coverage range, traffic values, and other inventory data aimed at keeping the device database updated.

With the security data obtained from the SIM itself, we collect the following information through the APIs offered by each of the communication operators:

- SIM card status

- Data about the used APN

- Connection status

- Enabled services (voice/data)

- Accumulated traffic during the last month.

- Geolocation data

WOCU-Monitoring’s M2M monitoring is fully adaptable for any type of device and communication operator, and its impact on the production network is minimal.

We want to remind you that thanks to the distributed architecture of WOCU-Monitoring, it’s possible to monitor hundreds of thousands of devices from a single console. Continuous monitoring identifies issues before they become service interruptions, improves efficiency, and allows optimization, maximizing return on investment (ROI).

This post is a brief introduction to OT environments; we will delve deeper into their monitoring soon.

WOCU-Monitoring, operational evolution.